Slip Joint Mechanisms Explained: The Elegant Simplicity of Traditional Knife Engineering

- Posted on

In the world of mechanical engineering, few mechanisms achieve the perfect balance of simplicity, reliability, and functionality found in the slip joint systems of traditional folding knives. While modern folding knives incorporate complex locking systems with multiple moving parts, slip joint mechanisms accomplish secure blade retention through elegant engineering principles that have remained virtually unchanged for centuries. Understanding the sophisticated simplicity of slip joint design reveals why these mechanisms continue to serve as the foundation for some of the world's most reliable and enduring cutting tools.

The slip joint mechanism represents one of humanity's most successful mechanical solutions, proving that complexity isn't always the path to superior performance. Through careful analysis of spring dynamics, material science, and precision manufacturing, traditional knife makers developed slip joint systems that provide reliable blade retention, smooth operation, and exceptional longevity while maintaining the serviceability and simplicity that modern mechanisms often sacrifice in pursuit of advanced features.

The engineering principles underlying slip joint mechanisms demonstrate how thoughtful design can achieve multiple objectives simultaneously: secure blade retention when needed, easy blade closure when desired, tactile feedback for user confidence, and mechanical simplicity for long-term reliability. These characteristics explain why slip joint mechanisms continue to find favor among professionals, collectors, and users who prioritize proven performance over contemporary innovations that may compromise fundamental reliability.

Fundamental Engineering Principles of Slip Joint Design

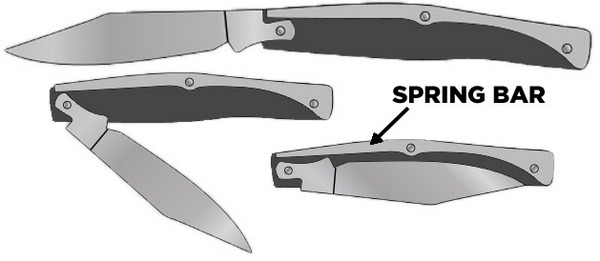

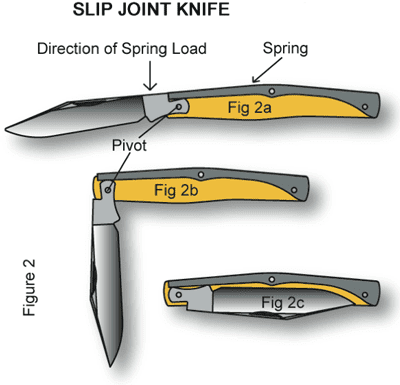

The slip joint mechanism operates on the principle of controlled friction and spring tension, utilizing a carefully designed spring system to create resistance that holds the blade in both open and closed positions while allowing deliberate repositioning when sufficient force is applied. This elegant solution eliminates the need for complex locking mechanisms while providing secure blade retention that serves the vast majority of cutting applications effectively.

The physics behind slip joint operation involve the interaction between spring force, friction coefficients, and mechanical advantage through leverage points carefully positioned along the blade tang. When properly engineered, these forces create distinct detent positions that clearly communicate blade status to users while providing sufficient retention to prevent accidental blade movement during normal cutting operations. The precision required to achieve optimal slip joint performance demonstrates the sophisticated engineering hidden within apparently simple mechanisms.

Spring geometry plays a crucial role in slip joint performance, with the shape, thickness, and heat treatment of the spring determining both the force required for blade movement and the longevity of the mechanism. Traditional knife makers developed spring profiles through empirical testing and generational knowledge transfer, creating designs that balance retention force with ease of operation while ensuring springs maintain proper tension throughout decades of use.

The interaction between spring tension and blade tang geometry creates the characteristic "snap" that users feel when blades reach full open or closed positions. This tactile feedback serves both functional and safety purposes, confirming proper blade positioning while alerting users to blade movement that might otherwise go unnoticed. The engineering precision required to achieve consistent, appropriate feedback demonstrates the sophisticated understanding of human factors that traditional knife makers incorporated into their designs.

Spring Design and Material Science

The heart of any slip joint mechanism lies in its spring system, typically consisting of a flat spring made from high-carbon steel that has been carefully heat-treated to achieve optimal elasticity and durability. The metallurgy behind effective slip joint springs requires balancing hardness for shape retention with toughness to prevent fatigue failure, creating springs that maintain consistent performance through thousands of operation cycles.

Traditional spring steels, such as 1084 or similar high-carbon compositions, provide the combination of strength, elasticity, and workability that slip joint applications demand. These materials achieve their performance characteristics through controlled heat treatment processes that create fine grain structures capable of withstanding repeated stress cycling without losing temper or developing fatigue cracks that could lead to premature failure.

The geometry of slip joint springs involves complex curves and angles that distribute stress evenly while providing the mechanical advantage necessary for effective blade retention. The spring profile must account for the range of motion required for blade operation, the force characteristics desired for user comfort, and the stress patterns that will develop during normal use. Master knife makers developed these profiles through experience and intuition, creating designs that modern engineering analysis confirms as remarkably sophisticated.

Spring attachment methods in traditional slip joint knives typically involve pinning or riveting the spring to the knife frame, creating a connection that must transfer operational loads while allowing the spring to flex freely. The precision required for proper spring attachment ensures that stress concentrations don't develop at connection points while maintaining the alignment necessary for smooth blade operation throughout the knife's service life.

Tang Design and Blade Integration

The blade tang in slip joint knives serves multiple critical functions, acting as the interface between the cutting edge and the spring mechanism while providing the leverage points necessary for blade operation. Tang design involves complex geometric considerations that affect both the mechanical performance of the slip joint and the user experience of operating the knife, requiring careful balance between strength, functionality, and manufacturing feasibility.

Traditional tang designs incorporate features such as the half-stop notch, which creates an intermediate blade position that prevents the spring from contacting the sharp edge while providing a secure carrying position. This engineering detail demonstrates the thoughtful consideration that traditional knife makers gave to both safety and functionality, creating mechanisms that protect both the user and the knife itself during storage and transport.

The transition area between the blade and tang requires precise engineering to ensure smooth spring contact while maintaining structural integrity under cutting loads. This region experiences complex stress patterns during both cutting operations and blade movement, demanding careful attention to geometry and heat treatment to prevent stress concentrations that could lead to blade failure or poor slip joint performance.

Tang thickness and profile must be precisely controlled to achieve proper spring engagement while allowing smooth blade movement through the full range of motion. The tolerances involved in tang manufacturing often measure in thousandths of an inch, requiring precision machining or careful hand-fitting to achieve optimal performance. This precision requirement explains why quality slip joint knives command premium prices and why cheaper alternatives often exhibit poor operation or premature wear.

Detent Systems and Position Control

The detent system in slip joint knives creates the distinct positions that users feel when opening or closing the blade, providing both functional blade positioning and user feedback about blade status. These detents result from the interaction between spring geometry and tang features, creating mechanical positions that require deliberate force to overcome while providing secure retention in normal use.

Primary detents occur at the fully open and fully closed positions, where the spring provides maximum retention force to prevent accidental blade movement during cutting or carrying. The engineering of these primary detents involves careful calculation of the forces required for both security and accessibility, ensuring that blades remain secure during use while still allowing intentional closing when desired.

Secondary detents, such as half-stop positions, provide intermediate blade positions that serve specific functional purposes like safety during transport or blade protection during storage. These secondary positions require additional engineering complexity in both spring and tang design, demonstrating the sophisticated functionality that skilled knife makers incorporated into apparently simple mechanisms.

The tactile quality of detent engagement provides users with crucial feedback about blade position and spring condition, allowing experienced users to assess slip joint performance by feel alone. This sensory feedback system enables users to detect wear, damage, or adjustment needs before they affect knife performance, contributing to the long service life that well-maintained slip joint knives provide.

Manufacturing Precision and Quality Control

The manufacturing precision required for optimal slip joint performance exceeds that of many modern mechanical devices, with tolerances that must be maintained across multiple components to achieve smooth operation and proper blade retention. Traditional knife makers developed hand-fitting techniques that allowed them to achieve this precision using basic tools, while modern manufacturers employ advanced machining and quality control systems to maintain consistency across production runs.

Spring tension measurement and standardization represent critical quality control points in slip joint manufacture, as variations in spring force directly affect user experience and knife performance. Quality manufacturers test spring tension using calibrated equipment to ensure consistency within acceptable ranges, while also conducting endurance testing to verify long-term performance under repeated use cycles.

Blade-to-spring fit requires precise control of multiple dimensions and surface finishes to achieve smooth operation without excessive wear or binding. The contact surfaces between blade tang and spring must be properly finished and aligned to prevent galling or premature wear while maintaining the precise fit necessary for optimal detent function and blade retention.

Assembly techniques for slip joint knives often involve hand-fitting and adjustment procedures that cannot be fully automated, requiring skilled craftspeople who understand the mechanical principles involved and can make the fine adjustments necessary for optimal performance. This human element in manufacturing helps explain why the best slip joint knives continue to be produced by companies that maintain traditional assembly methods and quality standards.

Operational Characteristics and User Experience

The user experience of operating a well-designed slip joint knife involves subtle but important feedback mechanisms that communicate knife status and condition to experienced users. The force required to open or close the blade, the smoothness of movement through the range of motion, and the positive engagement of detent positions all provide information about knife condition and proper operation.

Proper slip joint operation requires understanding the leverage points and techniques that optimize blade control while minimizing wear on the mechanism. Users who master these techniques find that slip joint knives provide superior control and predictability compared to many modern alternatives, particularly for precision cutting tasks that require exact blade positioning and controlled pressure application.

The break-in period for new slip joint knives involves the gradual wearing-in of contact surfaces and the settling of spring tensions to their optimal operating characteristics. During this period, the knife operation typically becomes smoother and more predictable as components achieve their final fit and finish through normal use, demonstrating how well-designed slip joints actually improve with age rather than deteriorating.

Long-term operational characteristics of quality slip joint knives include gradually increasing smoothness and more positive detent engagement as components wear into perfect fit. This aging characteristic appeals to users who appreciate tools that develop character and improved performance through use, creating a relationship between user and tool that modern mechanisms often cannot replicate.

Maintenance and Longevity Considerations

The maintenance requirements for slip joint mechanisms are remarkably minimal compared to modern locking systems, typically involving only periodic cleaning and light lubrication to maintain optimal performance. The simplicity of the mechanism means that most maintenance procedures can be performed by users without special tools or extensive mechanical knowledge, contributing to the long-term practicality of slip joint knives.

Cleaning procedures for slip joints focus on removing debris and accumulated lubricants that might interfere with smooth spring operation or cause premature wear of contact surfaces. The open design of most slip joint mechanisms allows easy access for cleaning, while the robust construction tolerates thorough cleaning procedures without risk of damage to delicate components.

Lubrication requirements for slip joints are minimal and must be carefully applied to avoid attracting debris that could interfere with mechanism operation. The types of lubricants suitable for slip joint use differ from those recommended for modern locking mechanisms, with traditional options often proving superior for long-term performance in slip joint applications.

Spring adjustment and replacement represent the most complex maintenance procedures for slip joint knives, typically requiring disassembly and specialized knowledge to perform correctly. However, the need for such major maintenance is rare in quality slip joints, with well-made examples often providing decades of reliable service before requiring spring attention.

Advantages Over Modern Locking Systems

Slip joint mechanisms offer several distinct advantages over modern locking systems that make them preferable for many applications and users. The legal compliance advantages of slip joints are significant, as non-locking folders are accepted in many jurisdictions that restrict locking knives, providing users with broader carry options while maintaining access to quality cutting tools.

The reliability advantages of slip joints stem from their mechanical simplicity and reduced number of precision-fitted components that must work in coordination. While modern locks may provide superior blade security under extreme loads, slip joints offer more consistent performance across diverse environmental conditions and usage patterns, particularly in applications where debris or contamination might interfere with complex locking mechanisms.

Serviceability represents another significant advantage of slip joint design, with most maintenance and repair procedures accessible to users with basic mechanical skills and tools. This serviceability ensures continued tool availability for users who depend on their knives for professional applications where downtime for factory service is impractical or impossible.

The tactile feedback provided by slip joint mechanisms offers advantages in applications where users need to assess blade position without visual confirmation, such as when working in confined spaces or low-light conditions. The distinct feel of properly functioning slip joints provides confidence and control that many modern mechanisms cannot match.

Professional Applications and Industry Adoption

Professional applications continue to favor slip joint mechanisms in many industries where reliability, legal compliance, and traditional functionality serve user needs better than modern alternatives. As explored in our comprehensive analysis The Craftsman's Choice: Why Traditional Folders Remain Essential Tools for Artisans, skilled craftspeople often prefer slip joint knives for their precision control, proven reliability, and integration with traditional techniques.

Industries with regulatory requirements or safety considerations may specify slip joint knives to ensure compliance while providing workers with effective cutting tools. The conservative nature of slip joint designs often receives approval from safety departments and regulatory bodies that might restrict more modern alternatives, making slip joints valuable options for institutional and corporate tool specifications.

The precision control possible with well-designed slip joints makes them particularly valuable for applications requiring exact blade positioning and controlled cutting pressure. Professional users who have mastered slip joint operation techniques often find that these traditional mechanisms provide superior performance for precision tasks compared to modern alternatives designed for different use patterns.

Emergency services and public safety applications sometimes favor slip joint knives for their legal compliance and reduced risk of accidental blade lockup that could interfere with critical operations. The deliberate operation required for slip joint blade closure provides an additional safety margin in high-stress situations where fine motor control might be compromised.

Comparison with Contemporary Engineering

When compared to contemporary knife engineering approaches, slip joint mechanisms demonstrate that effective solutions don't always require complex components or advanced materials. Our detailed comparison in Traditional vs. Modern Folders: When Classic Design Outperforms Contemporary Engineering explores specific scenarios where slip joint designs excel over modern alternatives, helping users understand when traditional approaches serve their needs better than contemporary innovations.

Modern locking mechanisms often achieve superior blade security under extreme loads but may sacrifice the reliability, serviceability, and legal compliance advantages that slip joints provide. The trade-offs involved in mechanism selection depend heavily on intended use patterns and user priorities, with neither approach universally superior to the other.

The manufacturing requirements for slip joints, while demanding precision, are often less complex than those required for modern locking systems with multiple precision-fitted components and tight tolerance requirements. This manufacturing advantage can translate into better value propositions for users who don't require the specific advantages that modern mechanisms provide.

Contemporary engineering analysis of traditional slip joint designs often reveals sophisticated solutions to mechanical problems that modern designers struggle to improve upon without adding complexity or compromising other desirable characteristics. This recognition has led some modern knife makers to incorporate slip joint principles into contemporary designs that combine traditional reliability with modern materials and manufacturing techniques.

Future Evolution and Modern Applications

The evolution of slip joint technology continues through improvements in materials, manufacturing precision, and design optimization that enhance traditional performance characteristics while maintaining the fundamental advantages that make slip joints attractive to modern users. Advanced steel alloys and heat treatment processes enable modern slip joint springs to achieve better performance and longevity than traditional materials while retaining compatibility with established design principles.

Modern manufacturing techniques, including CNC machining and advanced quality control systems, enable contemporary slip joint production to achieve consistency and precision that surpass what traditional hand-fitting methods could accomplish in high-volume production. These manufacturing improvements benefit users through more consistent performance and reduced break-in requirements while maintaining the essential characteristics that define quality slip joint operation.

Contemporary designers continue to explore variations and improvements to traditional slip joint designs that address modern user requirements while preserving the fundamental advantages that make slip joints attractive alternatives to complex locking mechanisms. These evolutionary developments demonstrate that traditional engineering principles remain relevant and valuable in contemporary applications.

Conclusion

The slip joint mechanism represents a remarkable achievement in mechanical engineering, demonstrating how thoughtful design can create elegant solutions that achieve multiple objectives through sophisticated simplicity rather than complex components. The enduring success of slip joint technology across centuries of use proves that effective engineering solutions transcend technological fashion, serving user needs through fundamental performance characteristics that remain valuable regardless of contemporary trends.

Understanding the engineering principles behind slip joint mechanisms provides insight into why these traditional designs continue to serve modern users effectively while offering advantages that contemporary alternatives often cannot match. The precision, reliability, and serviceability of well-designed slip joints make them valuable options for users who prioritize proven performance over advanced features that may compromise fundamental functionality.

The continued evolution of slip joint technology through improved materials and manufacturing techniques ensures that these traditional mechanisms will remain relevant for users who appreciate the unique combination of simplicity, reliability, and performance that slip joints provide. For those seeking cutting tools that embody the best of traditional engineering principles while meeting contemporary performance requirements, slip joint knives represent an enduring solution that bridges past and present through timeless mechanical excellence.